Researchers at MIT have come up with a Water Resistant Fabrics or to be more exact a water repellent coating that can be applied to any fabrics be it cotton, silk or otherwise. But you might be wondering why go to all that trouble when you’ve got raincoats and other stuff to be water resistant? The answer is simple many of that “other stuff” are not good for the body and do not degrade fast when thrown out into the environment. So most of that other stuff has been banned by many environmental groups and also because they don’t meet safety regulations.

The new water resistant fabrics not only adds repellency to its features but is also more effective at doing what it does than current methods. What’s more is that it can be applied to any type of material be it silk or cotton.

The problem with current techniques:

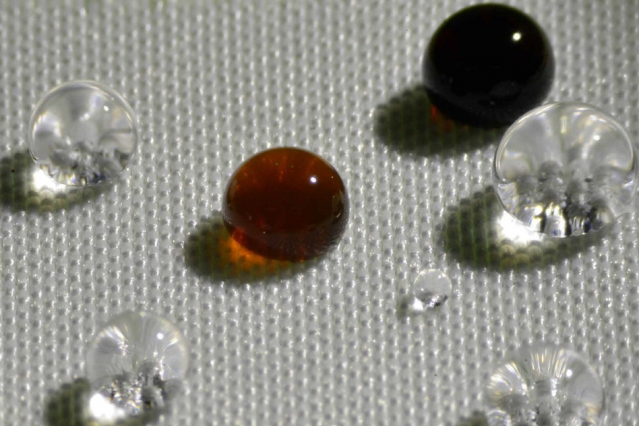

As mentioned earlier besides being a safety concern and damaging the environment most of the current practices are basically water- resistant and not really water repellent. Water resistant means that the fabric will eventually get soaked through with water but at a lesser rate than non- water- resistant materials. But with water- repellant you get a fabric from which water bounces back.

The current practice of water resistant fabrics uses long chain polymers and are in the process of being phased out by regulatory authorities for obvious reasons.

The problems of coming up with a new water resistant fabrics:

The current long chain polymers were found to be effective in repelling water and so they became the industry norm but with new regulations in the pipeline, researchers were looking for alternative methods.

Long chain polymers were used as opposed to short chain polymers because of their water resistant properties. The shorter chain polymers were found to be not that effective when it came to repelling water that is until now.

Another problem with the current technique was that the water resistant fabrics had to be immersed in a liquid to add to its water resistant properties and then dried out. During this process the fabric would be clogged and another process is used to blow air through the fabric to reopen its pores which again removed some of its water resistant properties.

Overcoming the Problems in making the new water resistant fabrics:

Researchers then used a combination of shorter chain polymers which has some water resistant properties and enhancing it with an additional chemical process. Add to that another coating process called initiated chemical vapor deposition, which does not need the fabric to be immersed in water later on and can be made using low temperatures, you get yourself a new and improved water resistant fabric.

This breakthrough water resistant fabrics do not only work on fabrics either it can even be applied to surfaces such as paper, opening up a host of other applications.

Scientists are well on their way to perfecting this water resistant fabrics and getting it patented.

How SASE Solutions Empower Productive Workforces in a Digital Era

How SASE Solutions Empower Productive Workforces in a Digital Era  Excel vs PDF: Which Dominates Document Sharing in 2025? (Data-Driven Comparison)

Excel vs PDF: Which Dominates Document Sharing in 2025? (Data-Driven Comparison)  TitaniumInvest.com Money 2024: AI‑Driven Tools Outperform Traditional Banking

TitaniumInvest.com Money 2024: AI‑Driven Tools Outperform Traditional Banking  Why Your Link Building Efforts Might Fail

Why Your Link Building Efforts Might Fail  How to Request or Give Remote Control in a FaceTime Call on iPhone

How to Request or Give Remote Control in a FaceTime Call on iPhone  The Rise of Intelligent Automation in Business Operations

The Rise of Intelligent Automation in Business Operations  The Best Ideas for Designing Your Custom Printed Ring Binder

The Best Ideas for Designing Your Custom Printed Ring Binder  How Technology is Changing the Way We Play Hearts

How Technology is Changing the Way We Play Hearts  The Rise of Open Source: A Journey to Innovation and Collaboration

The Rise of Open Source: A Journey to Innovation and Collaboration